Construction of refrigerated and storage rooms

The construction of cold rooms and cold stores is a complex process that requires careful planning and execution. These facilities are essential for the storage of foodstuffs, medicines and other temperature-sensitive materials. Here are the basic steps and components to consider when building cold rooms and cold storage facilities:

1. Planning and design

The first step in the process is the planning and design of the cold chamber or room. This involves determining the required volume, layout and specific temperature and humidity requirements. It is important to consult with refrigeration professionals to ensure the design will meet all standards and regulations.

2. Selection of equipment

The next stage is the selection of suitable equipment. The main components include:

Refrigeration unit: It provides the necessary cooling through a compressor, condenser, evaporator and thermoregulating valve.

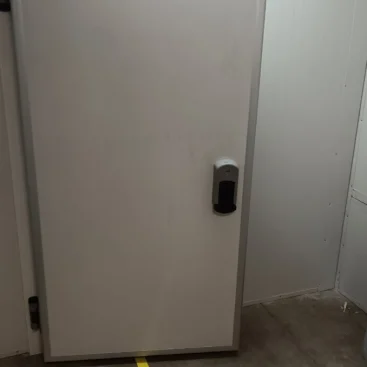

Isolacioni panels: They help maintain a constant temperature inside the chamber or room. Polyurethane panels with high thermal insulation are usually used.

Ventilation system: It ensures air circulation and even temperature distribution.

Control system: This system monitors and regulates temperature and humidity in real time. It can be automated for easier management.

3. Assembly and installation

The installation of the cold chamber or room begins with the preparation of the base and the installation of the insulation panels. The refrigeration unit, ventilation system and control system are then installed. All connections must be well sealed to prevent cold loss.

4. Testing and commissioning

Upon completion of installation, the system must be tested for proper operation. All parameters such as temperature, humidity and equipment operation are checked. If everything is within normal limits, the cold store or room can be put into operation.

5. Maintenance and monitoring

Regular maintenance and monitoring is necessary to ensure the longevity and efficiency of a cold room or space. This includes checking the refrigerant, cleaning the filters and inspecting the insulation. Regular maintenance helps prevent damage and reduce energy costs.

Building cold rooms and cold rooms requires attention to detail and professionalism. With the right approach and quality equipment, these facilities can provide reliable storage for a variety of products and materials while maintaining their quality and safety.